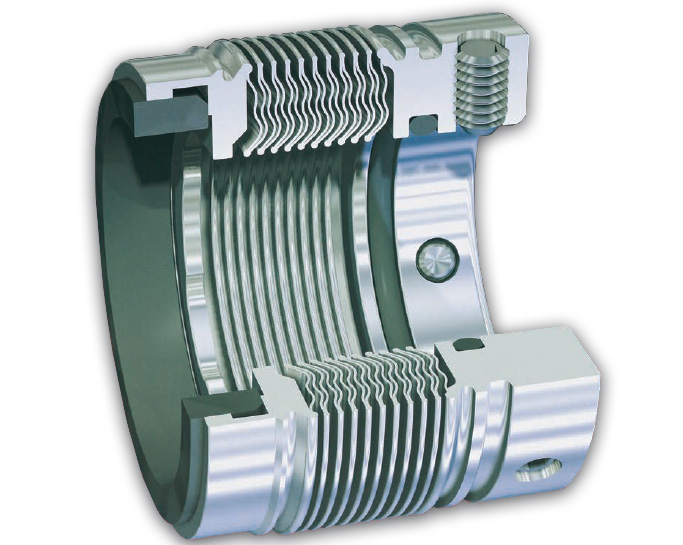

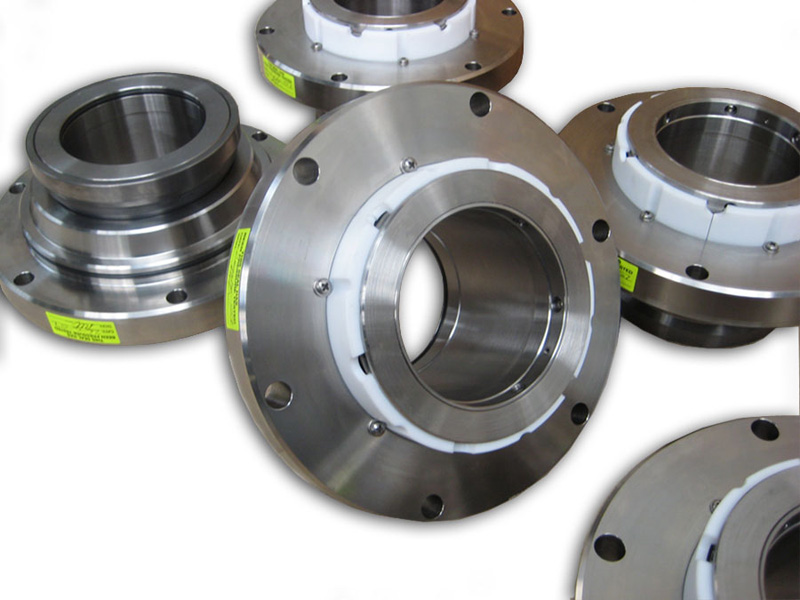

200series

Welded Metal Bellows Seal

Features

- Inherently pressure balanced – no steps needed for shaft or sleeve.

- Minimum seal face loading reducing seal face wear.

- Centrifugal cleaning action expels materials which clog pusher type seals.

- Bellows action overcomes the hang-up problems associated with pusher seals.

- Inconel 625 10 convolution welded metal bellows [201] offers a combination of high mechanical strength and corrosion resistance.

- Bellows plates shaped for extended seal performance.